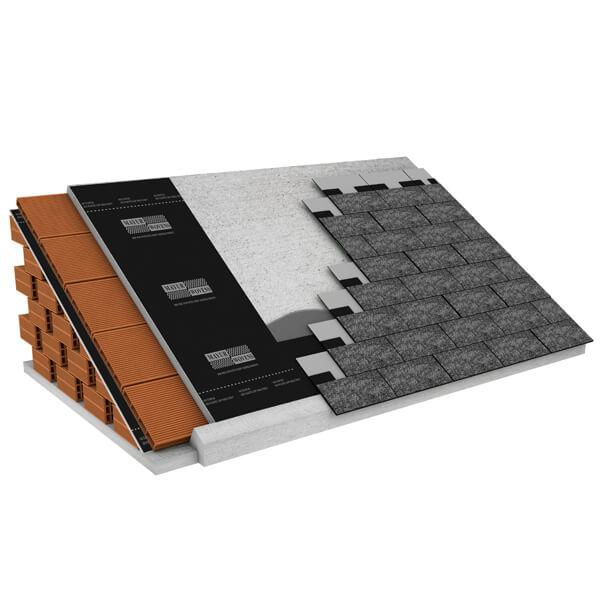

The roofing industry had been stagnant for several decades. The challenge was to improve the performance characteristics of roofing. Keeping in Line with Technological Advancements, we came up with a product which is lightweight, & designed as an alternative to asphalt saturated felt. Our shingle underlayment sheet features a woven polymeric scrim for increased strength and reduced slippage between underlayment and the roof sheathing. A textured top surface fabric improves walkability during installation. Also, our synthetic roof underlayment is highly resistant to tear, whether it is by walking on it or UV breakdown.

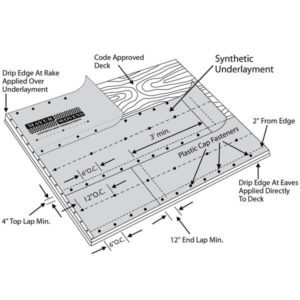

Mayur’s Synthetic Roof Underlayment can be mechanically fastened to several different substrates, making it an excellent underlayment solution for new and re-roofing applications.

Our Synthetic roof underlayment provides a secondary weather barrier to help fortify roofs from wind-driven rain or simple exposure to the elements. Our synthetic underlayment is designed to enhance the life of the roof. Equally as important, this moisture resistant synthetic underlayment is a water barrier built to stand strong when its needed the most. Also our Synthetic Roof Underlayment is a highly engineered and coated with woven which combines a durable and high strength design with a fibre grip walking surface.